Smith's Clear Penetrating Epoxy Sealer - Warm Temp

Smith's Penetrating Epoxy Sealer - Warm Weather Formula, 2 Gallon Kit

- Use in Temps From 65 to 85 Deg

- Thin asWater Penetrates Deeply

- Adheres Strongly to Substrates

Availability:

Description

Smith's Clear Penetrating Epoxy Sealer (CPES) has two primary uses in the marine industry, where wood rot is a fact of life:

• Its super thin epoxy formulation and long working time allows it to deeply penetrate and stabilize rotted wood for subsequent restoration. Unique resin chemistry allows the Penetrating Epoxy Sealer to absorb any residual moisture in the wood - making it the most effective product available for treating rot.

• Additionally, those same deep penetrating characteristics make CPES ideal as a wood sealer, and also as a primer for painting wood - where it forms a tenacious bond to paints, varnishes, .

CPES also seals concrete, mortar, and other consolidated porous materials, and is an essential component for the effective treatment of osmosis blisters on fiberglass hulls.

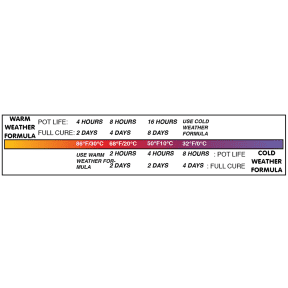

This Warm Weather Formulation of CPES is typically selected for use in temperatures from 65°F to 85°F. If the humidity is low, this range can be pushed into the low 90s.

Refer to the accompanying temperature range graphic. (Be sure to click on the image to expand it for easier viewing.)

For wood in good condition, Smith's Clear Penetrating Epoxy Sealer makes an excellent stand-alone sealer.

It is also a superior adhesion promoter/primer for paint and varnish.

Complete sealing is generally achieved in just one treatment. With a reputation as, "the cure for paint failure", Smith's Epoxy Sealer is an ideal undercoat on plywood, building siding, etc.

For treating and restoring rotted wood, you need to use both components of Smith's wood restoration system:

After removing the observable rotted wood, use Smith's Penetrating Epoxy Sealer to seal the wood and solidify any remaining rot.

Then apply Smith's Filler Epoxy to fill the voids left when you cleaned out the crumbly rotted wood.

Finally, apply a final coat of Penetrating Epoxy Sealer as an adhesion promoter for subsequent paint coatings.

Special features of Smith's Clear Penetrating Epoxy Sealer

• Longer working time than other epoxies allows maximal wood penetration

• Solvent blend dissolves blocking sap, oil and moisture found in wood – allowing it to penetrate more deeply

• Changes rotted wood into epoxy-impregnated cellulose which resists further attack by rot-causing fungi while reinforcing the wood

• Exhibits toughness and flexibility comparable to the original wood so it moves with the wood, preventing cracks that would allow water and fungus spores to re-enter

• Allows wood to continue breathing - so it doesn't trap moisture under the surface

• Treated wood is highly resistant to a re-occurrence of dry rot

• Sealer forms an exceptionally strong bond with a wide variety of varnishes, paints, adhesives, and caulking – assuring adhesion to the substrate wood

• Not limited to boats, Smith's Penetrating Epoxy Sealer is also ideal for repairing and restoring wood rot in homes, basements, garages, barns, and other structures

• CPES can also consolidate crumbly concrete, and old mortar between bricks

• Apply using brush, roller or immersion; do not spray

• Clean-up solvent will dissolve and clean-up sealer while still wet; once cured, no clean-up solvent is effective

• Filler Epoxy for re-building rotted sections is high strength, light weight, non-sagging, and easily sanded

• Filler Epoxy must be used over a coat of the Penetrating Sealer to ensure the strongest bond

• The moisture content of treated wood must be less than 20% so as to not overwhelm the moisture absorbing capabilities of the sealer resin

Heavy on the technical side...

Only recently was it discovered that paint peels due to air-borne fungi rotting the wood in a thin layer just under the paint layer. The peeling paint problem has increased since the outlawing of lead (a preservative), and the lower rot resistance of the faster grown wood demanded by today's lumber mills.

Smith's Penetrating Epoxy utilizes a unique solvent and resin system to attack the air-borne wood rot fungi as no other product does.

It penetrates wood better than other rot treatments because its unique solvents combine with the naturally occurring residual water in all wood – thus penetrating deeper.

Competing penetrating epoxies made using water-repellent petrochemicals such as benzyl alcohol cannot do this. None of Smith's products use benzyl alcohol.

Thin as water, the solvents in CPES not only dissolve moisture in the wood, they also dissolve sap and oils — allowing the epoxy to gain access to the wood's xylem tubes, along which it flows deep into the wood.

Specifications

653071420910

Product Options

| Selected | SKU # | MFG # | Availability | Size | Price | Quantity | |

|---|---|---|---|---|---|---|---|

| SKU #: 91164 | MFG #: SMT-WWPEGAL | 5 In Stock Ships immediately | 2 Gallon Kit | $327.10 Kit | |||

| SKU #: 91163 | MFG #: SMT-WWPEQT | 21 In Stock Ships immediately | 2 Quart Kit | $101.97 Kit | |||

| SKU #: 91162 | MFG #: SMT-WWPEPT | 7 In Stock Ships immediately | 2 Pint Kit | $67.02 Kit |