Coosa Composite Board: Perfect for Marine Use

Are you looking for a reliable, lightweight material for your marine composite applications? Look no further than Coosa Board. This fiberglass-reinforced composite panel is the ideal choice for boat builders and marine enthusiasts alike. In this article, we will explore the technology behind Coosa Board, why it's the perfect option for marine applications, its different variants and features, popular uses, and fabrication techniques. We'll also delve into the limitations of Coosa Board and what you need to know before using it in your projects. With Coosa Composites being recognized as a leader in the marine industry, you can trust that their products will meet your expectations. Read on to find out why Coosa Board is an excellent replacement for plywood in marine applications.

Exploring Coosa Board

Renowned for durability and water resistance. Exceptional stiffness, resistance to mold, UV, and water absorption make them ideal for marine applications.

The Technology behind Coosa Board

The Lightest Fiberglass Reinforced Composite Panel

Ideal for structural marine applications, the Coosa panel offers easy workability, excellent insulation properties, and versatility for boat floors, transoms, and bulkheads.

Why Choose Coosa Composites for Marine Applications?

Coosa Composites are the ideal choice for marine applications due to their resistance to water absorption, preventing issues like rot, mold, mildew, and delamination. With a wide range of products available, they offer excellent customizability options to meet specific design requirements.

A recognized leader in the marine industry for its structural superiority, resistance to water absorption, and 30-40% lighter weight compared to marine plywood. Coosa panel excels in marine composite applications, so say goodbye to heavy, water-loving lumber!

Coosa Board Variants and Their Features

Bluewater 26 offers high strength for structural applications. It is a stronger and stiffer alternative to the Bluewater 20 and can be used as a direct replacement for plywood in all structural applications. Bluewater 26 is Coosa's strongest and stiffest panel, yet still provides at least a 30% weight savings over plywood.

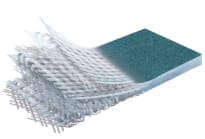

Bluewater 20 is a medium-density (20 lb/ft³), polyurethane foam board reinforced with layers of continuous strand fiberglass, as well as woven roving for extra stiffness. It is a lighter weight, economical alternative to the Bluewater 26, yet maintains substantial stiffness, a high strength-to-weight ratio, and can still be used as a direct replacement for plywood. It's typically used in semi-structural applications such as stringers, decking, hatch lids, cabinetry - that are more critical than where the less stiff Nautical Series will suffice. Best of all, Bluewater 20 is available in a wide range of thicknesses - which can eliminate the need to laminate sheets in order to achieve your desired thickness.

Nautical 24 is a medium-duty, high-density polyurethane foam board reinforced with layers of continuous strand fiberglass. It is a stronger and stiffer alternative to the Nautical 20 and can be used as a direct replacement for plywood. It is typically used as a low-stress structural component.

Nautical 20 is a light-duty, medium-density polyurethane foam board reinforced with layers of continuous strand fiberglass. It is a lighter weight, economical alternative to the Nautical 24 but can also be used as a direct replacement for plywood.

Limitations of Coosa Board

Understanding the constraints of Coosa board is crucial for informed decisions, including thickness limitations, ventilation needs, and susceptibility to damage during transportation. Careful handling is essential. The only real downside to Coosa is it's increased cost - but that can be easily offset when considering durability and ease of use.

Popular Uses of Coosa Board

Fabrication Techniques with Coosa Board

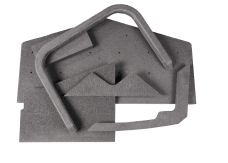

Fabrication techniques with Coosa panels involve easy cutting, routing, and shaping using standard woodworking tools. Woven roving reinforcement enables precision machining, allowing intricate designs and seamless integration into complex structures. Coosa composite panels can be bonded, laminated, and molded for desired forms. The absence of voids and knots, along with consistent material properties ensures structural reliability and uniform performance. Its versatility, longevity, and durability make it an ideal choice in the marine industry.

Frequently Asked Questions

Is Coosa board worth it?

Coosa board is definitely worth it for marine composite applications. Its durability and versatility make it a lightweight alternative to plywood and fiberglass. With resistance to rot, moisture, and UV rays, Coosa board ensures a long-lasting investment despite a slightly higher cost.

What is comparable to Coosa board?

Other composite materials with similar properties to Coosa board include marine plywood, PVC foam board, and fiberglass-reinforced plastic. It is important to consult with a marine industry professional to determine the best material for your specific project based on factors such as strength, durability, weight, and cost.

Is Coosa board as strong as plywood?

Conclusion

Coosa Board is the perfect choice for marine composite applications due to its exceptional qualities. It is a lightweight, durable, and versatile material that offers superior strength and performance. Coosa Board is backed by advanced technology and is recognized as a leader in the marine industry. With its multiple variants and features, it can be used in a wide range of applications, including boat building, flooring, and structural components. However, it's important to note that Coosa Board does have some limitations, and it's crucial to understand them before using them in your projects. Overall, Coosa Board provides an excellent replacement for plywood in marine applications, offering the perfect balance of strength, durability, and weight savings. Trust Coosa Composites for all your marine composite needs.

Ask for help!

If you’re still unsure if composite boards are right for your project, call us at 206-632-4462, and one of our representatives can help you decide!