Boat Washer Fasteners

42 results

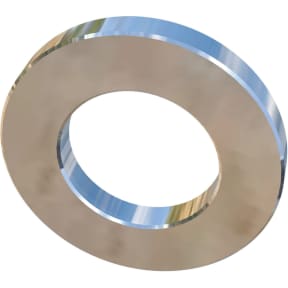

Fasco Fastener

Flat Washer -SS

Available in 20 options

$10.31 - $44.33

Fasco Fastener

Lock Washer

Available in 12 options

$1.98 - $26.80

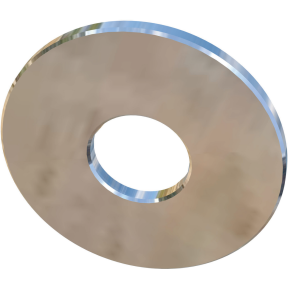

Fasco Fastener

Fender Washer

Available in 9 options

$9.69 - $43.08

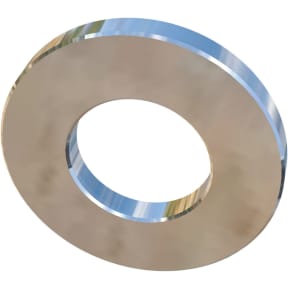

Fasco Fastener

Flat Washer - Bronze

Available in 6 options

$12.49 - $93.53

Fasco Fastener

Lock Washer - Metric

Available in 3 options

$7.37 - $9.37

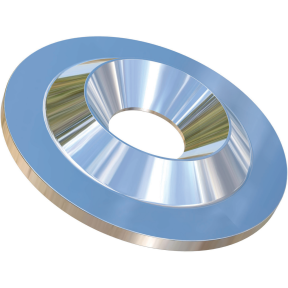

Fasco Fastener

Finishing Washer

Available in 6 options

$12.19 - $29.70

Fasco Fastener

Finishing Flange Washer

Available in 2 options

$18.75 - $24.08

Fasco Fastener

Brass Finish Washers

SKU: 203954 | Item ID: 266 2006

$12.17

Maxwell

NLP Washer Wave

SKU: 186402 | Item ID: MXW SP0468

$12.00

Fasco Fastener

Lock Washers

Available in 5 options

$13.98 - $47.45

Midland Metals

Garden Hose Rubber Washers

Available in 2 options

$0.26 - $0.43

Fasco Fastener

Metric Fender Washers

Available in 4 options

$17.65 - $26.72

Fasco Fastener

Finish Washer

Available in 3 options

$9.49 - $23.98

Fasco Fastener

Fender Washer - Bronze

Available in 5 options

$22.54 - $194.11

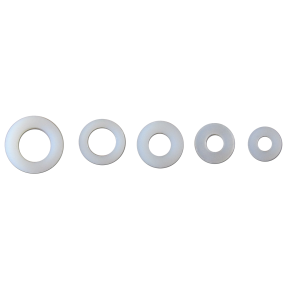

Fasco Fastener

Nylon Flat Washer

SKU: 371388 | Item ID: 272 3088

$24.98

Fasco Fastener

Flat Washer - Metric

Available in 4 options

$18.36 - $29.12

Fasco Fastener

Flat Washer - Nylon

SKU: 72220 | Item ID: 272 1101.031.0.120

Fasco Fastener

Flat Washer - Nylon, Wide Wall

SKU: 370313 | Item ID: 272 2981

$16.42

Groco

Washer 504F

SKU: 17031 | Item ID: GRO 504F

$0.90

Sherwood

Water Pump Washer

SKU: 129184 | Item ID: SHW 15959

$3.47

Freeman Marine

Nylon Washer 0413-2005

SKU: 162207 | Item ID: FRE 0413-2005

$3.36

Groco

Nylon Flat Washers

SKU: 126830 | Item ID: GRO PFW-2 SET

$5.39

Maxwell

Tab Washer

SKU: 431812 | Item ID: MXW 4220

$8.00

Maxwell

Circlip

SKU: 210643 | Item ID: MXW SP0846

$11.00

Fasteners Inc

Flat Washer - Galv.

Available in 2 options

Fasteners Inc

Lock Washer - Galv.

Available in 3 options

Fasco Fastener

1008 Piece Fastener Kit

SKU: 429187 | Item ID: 268 KIT-KP9097F

$163.40

Handi Man Marine

Flat Washer - SS

SKU: 130461 | Item ID: S/J 810022

Maxwell

Flat Washer

SKU: 186398 | Item ID: MXW SP0413

$2.32

Maxwell

Washer Spring

SKU: 390517 | Item ID: MXW SP0467

$1.29

Allied Titanium

Washer - Split Lock - Grade 5 Titanium

Available in 6 options

$68.56 - $115.51

Allied Titanium

Washer - Flat - Grade 5 Titanium

Available in 24 options

$31.79 - $85.98

Allied Titanium

Washer - Split Lock - Grade 2 Titanium

Available in 3 options

$75.08 - $105.12

Allied Titanium

Washers - Fender - Grade 2 Titanium

Available in 5 options

$59.32 - $92.33

Allied Titanium

Washer - Split Lock - Metric - Grade 5 Titanium

Available in 2 options

$71.90 - $105.39

Allied Titanium

Washers - Split Lock - Metric - Grade 2 Titanium

Available in 2 options

$15.21 - $56.33

Allied Titanium

Washers - Flat - Metric - Grade 2 Titanium

Available in 8 options

$10.67 - $74.62

Allied Titanium

Washer - Flanged Finishing - Grade 2 Titanium

SKU: 1023404 | Item ID: ALT 76940

$48.71

Allied Titanium

Washer - Fender - Grade 5 Titanium

Available in 5 options

$53.17 - $74.54

Allied Titanium

Washer - Flat - Grade 2 Titanium

Available in 23 options

$12.18 - $90.96

Allied Titanium

Washers - Flat - Metric - Grade 5 Titanium

Available in 8 options

$35.87 - $67.77

Allied Titanium

Washer - Fender - Metric - Grade 5 Titanium

SKU: 1023853 | Item ID: ALT 52732