Description

The top of the line.

Grind, blend, finish and deburr longer, faster and with greater productivity than ever on all metal types with Cubitron II™ Roloc™ Disc 984F.

A complete carbon steel and stainless steel solution.

When you're using a disc sander, you're relying on the edge of your abrasive disc to grind, blend and finish.

If you've been frustrated by edge failures, make the switch to Cubitron™ II Roloc™ 984F.

Its extra-durable edge backing – combined with sharp, precision-shaped grains – make this one tough disc that lasts longer and performs better.

In some applications, users see twice the life over traditional discs.

• Premium 3M™ ceramic grain Roloc™ disc constructed on a very heavy YF weight, water resistant laminated polyester cloth backing for added durability

• Fastest cut — precision-shaped grain self-sharpens for consistent and continuous cutting power with less pressure

• Use for deburring, deburring edges, grinding, parting line removal, prepping metal prior to paint, right angle grinding, weld cleaning, weld removal and finishing

• Use on virtually all metal types - carbon steel, stainless steel, nickel alloy, titanium, and even aluminum

• Fewer edge failures - durable edge backing provides extended edge retention - won't fray or wear out prematurely

• Cool running — precision-shaped grain and grinding aid allows discs to run cooler

• Quality 3M™ Roloc™ buttons for an easy on/off attachment that stays in place

• One of the longest-lasting Roloc Discs available in the industry

• Use wet or dry

• Open coat

The hardness of the disc pad can affect the pressure applied and cut.

Choose from 3M’s variety of disc pads to select the ideal degree of aggressiveness or conformability for your job requirements.

Don’t fear the edges — while edges on the workpiece may have caused premature edge wear on other discs, they can actually help precision-shaped grains fracture and extend the life of a Cubitron II Roloc 984F disc.

Heavy on the technical side...

Cubitron II is a revolutionary 3M™ precision-shaped ceramic grain technology.

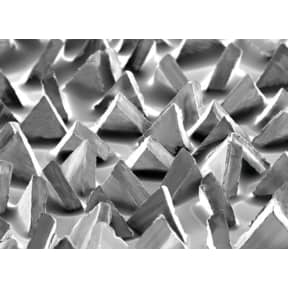

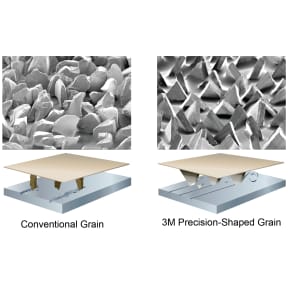

It is engineered with mineral crystals that are sharp-edged, fast-cutting, and shaped like pyramids which are electrostatically oriented so they point upwards - like sharp peaks. The peaks act like individual cutting tools - slicing through metal, wearing evenly, running cooler, and providing super-long life and cutting consistency.

Mineral breakdown is optimized because, instead of getting rounded as they wear, the pyramids continuously fracture to form brand new, sharp, cutting edges — maximizing performance and disc life.

By contrast, conventional ceramic abrasive grain is irregular in shape. Instead of a clean slicing action, the grain "plows" through the metal, causing heat build up, slower cutting and shorter life. See illustration at left.

Specifications

000511412774

50051141277092

30051141277098

Product Options

| Selected | SKU # | MFG # | Availability | Grade | Diameter | Price | Quantity | |

|---|---|---|---|---|---|---|---|---|

| SKU #: 390367 | MFG #: 051141-27709 | 6 In Stock Ships immediately | 60 | 2" | $88.61 Box | |||

| SKU #: 390440 | MFG #: 051141-27710 | Special Order Only | 60 | 3" | $441.66 | |||

| SKU #: 390441 | MFG #: 051141-27717 | Special Order Only | 80 | 2" | $82.55 Box | |||

| SKU #: 390442 | MFG #: 051141-27718 | Special Order Only | 80 | 3" | $110.42 Box | |||

| SKU #: 391303 | MFG #: 051141-28124 | Special Order Only | 60 | 1" | $192.51 | |||

| SKU #: 437635 | MFG #: 051141-28213 | 3 In Stock Ships immediately | 36 | 2" | $92.65 Box |