3-1/8" Heavy Duty Commercial Bumper for Vessel or Dock, 60 ft.

- For Vessel or Dock

- 20, 40 & 60 ft Lengths

- "Key" Bore Fastener Channel

Availability:

Description

100 Series Duramax® Tapered D-shaped Hollow Core Bumper is used in marine and industrial applications.

This popular marine fender/bumper product provides impact protection on both vessels and docks.

It also is used to provide protection for trucks, loading docks, forklifts and other equipment.

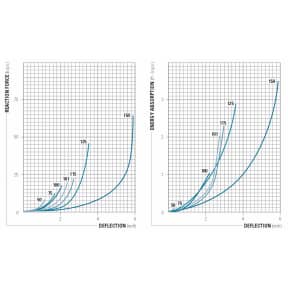

Extruded Hollow Rubber Fenders like these exhibit higher energy absorption than solid cores due to greater deflection for given loads. They comprise the larger portion of the fendering industry for both harbor and vessel service.

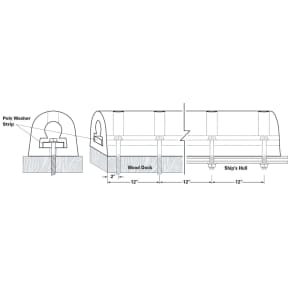

This "Key" Bore version of the 100 Series Bumper is designed with an internal flat slot, allowing for the insertion of a continuous plastic "washer strip" that prevents the mounting fastener heads from penetrating the bumper's back wall.

You can count on "Duramax" bumpers to withstand harsh environments. Made from EPDM, this rubber compound is formulated to resist weathering and ozone attack.

Duramax® bumpers can last 4x longer than styrene-butadiene rubber (SBR) or butyl bumpers. Ozone can cause cracking in these lower cost compounds, particularly under stress. EPDM resists sunlight, oxidation, seawater and many chemicals.

Offered in three colors: black, non-marking gray, and white. Fisheries stocks the black bumper, but we can special order the other colors on request - inquire at 800-426-6930.

• Black, non-marking gray and white EPDM compounds available

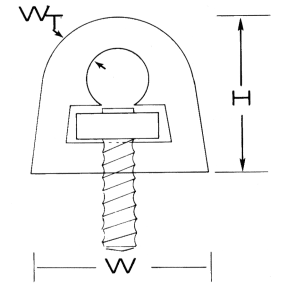

• 100 Series heavy duty extruded Tapered D-shaped bumper is available with either "Key" or "D" internal cross sections

• Sold only in factory pre-cut lengths

• Can be fastened by bolts or lag screws (use of Duramax Washer Strip is highly recommended; see Accessory Products)

Use 90° Molded Insert Corner/End Cap to join sections of bumper around dock corners, or to "finish" the end of a section with an end cap; see Accessory Products.