Black Widow Racing Antifouling - Multi-Season

Black Widow Racing Antifouling, Black - Gallon

- Hard, Slick, Burnishable, Fast

- Dual Biocides

- Four Low-Friction Agents

Description

Black Widow is the slickest, fastest, ultra-smooth, burnishable racing finish available. It makes an excellent paint for the bottom of any boat where speed is the number one priority — racing sailboats, high performance offshore powerboats, and more. Black Widow is easily burnishable to a metallic “gun-metal” shine.

Black Widow bottom paint is in a unique category – combining the best attributes of both hard and ablative technologies.

It works by leaching biocides just as a traditional hard paint does. However, once the surface biocide is gone the paint film will break down in water and “powder off” – exposing a new layer of biocide.

Black Widow's self-polishing surface resists build-up and can be burnished to a porcelain-like racing finish.

Traditional hard racing finishes typically have little or no antifouling capabilities, but Black Widow provides highly effective, dual-biocide, multi-season protection against aggressive fouling and slime.

Black Widow also contains four robust slickening agents: molybdenum disulfide, PTFE, graphite and silicon.

Its dual biocides provide multi-season protection in all waters (performs best when the boat is used periodically).

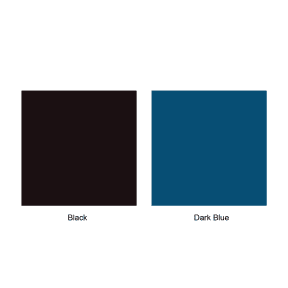

The primary differences between Black Widow and Vivid ‐ Pettit's similar high-performance antifouling paint – is that while Black Widow has those slickening agents and only comes in black or dark blue, Vivid comes in six bright colors (customizable by mixing) and lacks the extra slickening agents.

Black Widow features –

• Slickest, fastest and easiest to clean racing paint

• Provides high performance, multi-season antifouling protection

• Dual biocides: 25% cuprous thiocyanate (protects against hard growth), and 2.8% zinc pyrithione (protects against soft growth)

• Flat finish; can optionally be polished to a mirror-like finish *

• May be applied over most aged, hard antifouling coatings - consult Pettit compatibility chart for specific recommendations

• Not for use on aluminum hulls or outdrives without proper priming; see Tech Sheet and Accessory Products

• Can be applied by brush, 3/16" (max.) solvent resistant roller, or airless or conventional spray

• Thinner: Pettit 120 or 120VOC Brushing Thinner; 121 Spraying Thinner

• Theoretical coverage is 440 ft²/gallon; 2 thin coats recommended, but three if spraying. If you are planning to burnish the finish, apply an additional coat (see below); 73% solids (by vol.)

• Excessive film thickness may cause poor adhesion and film cracking

• Do not scrub or clean for the first 6 months in the water; wait at least 3 months between scrubbings thereafter

Heavy on the technical side...

* Burnishing of the Black Widow surface to create a slicker finish can be done, in steps, with 400 thru 5000 grit wet-or-dry sandpaper after the coating has dried for at least 48 hours.

More depth can be achieved by using a buffer at 1750 rpm with a wool buffing pad and Meguiar's Diamond Cut Compound (M85); see Accessory Products.

This compound creates an effect similar to applying a finishing glaze.

Burnishing Black Widow with the Meguiar's Diamond Cut wiil give you a "gun-metal" like racing finish without compromising antifouling performance.

When burnishing, it is recommended to apply a third (if rolling) or fourth (if spraying) coat of Black Widow, as the burnishing process will remove at least half of the top coat.

Refer to the Performance Antifouling Spray and Burnishing Guide link in this entry for more information.

Specifications

1186906

725469029057