Hawk Epoxy C3 Fast Cure Catalyst - 0.87 Gal - Size 3 (Blue Tag)

Description

Hawk Epoxy is a clear, low viscosity, low-blush system designed for ease of use in the widest variety of construction and repair projects.

The flexibility of Hawk Epoxy lies in its wide range of catalysts and fillers to adapt to any application requirements.

C3 Fast Cure Catalyst is designed for use with Hawk Epoxy R1 Resin in construction and repairs for superior adhesion, strength, bonding, filling, and moisture barrier qualities.

C3 Fast Cure Catalyst is ideal for these two situations:

• When ambient temperatures are cool - and other catalysts kick off too slowly, and provide overly long tack and cure times

• When you want a fast cure at normal room temperatures - when a particular job needs to cure in a hurry for engineering or schedule reasons

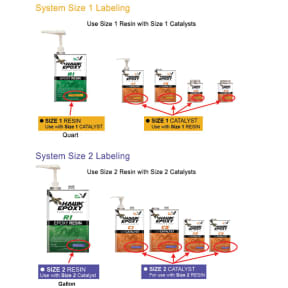

Hawk Epoxy resins and catalysts are each available in four System Sizes, with a color-coded tag on every can.

The mix ratio varies depending on which catalyst is being used.

Just be sure to choose the same System Size (1, 2, 3, or 4) for both the resin and catalyst to ensure you purchase the correct combination. The bright color-code tag on each can will help you.

Application information:

• Minimum recommended application temperature: 40°F

• Pot life of a 4 oz (110 gm) batch: 9 - 12 min (at 77°F)

• Thin film (6 mils) tack/working time (not wet): 60 - 70 min (at 77°F)

• Thin film (6 mils) solid cure: 6 - 8 hr (at 77°F)

• Thin film (6 mils) full cure/working strength: 1 - 4 days (at 77°F)

• Mix ratio by volume: 5:1

• NOTE: Do not overcoat with Sea Hawk Marine Wood Varnish

Heavy on the technical side...

• Pot Life

Remember - epoxy cures faster at higher temperatures, and in thicker applications. Mix in smaller batches and wide, shallow containers to prolong pot life and working time.

• Storage Life

Storage temperature: 40°-90°F (32°-4°C).

Keep containers sealed and in a well-ventilated area.

Hawk Epoxy components have an extended shelf life, and will last for several years. After extended storage, be sure to mix a small amount of Hawk Epoxy R1 Resin and Hawk Epoxy Catalyst (at the correct ratio) and ensure proper curing before proceeding to a larger project.

Hawk Epoxy Catalysts, (C1, C2, C3 and C5) will darken in color with extended storage times. However, this color change will not affect the physical characteristics of the finished project.

Hawk Epoxy R1 Resin may thicken with extended storage times, and may require thorough mixing before combining with Hawk Epoxy Catalysts.

If Hawk Epoxy R1 Resin or a Hawk Epoxy Catalyst goes through extreme hot and cold temperatures, say 32°F or below, it may get hard and mineralized in appearance. The mineralization will not affect the physical characteristics of the finished product. To eliminate mineralization, heat product to no less than 110°F for 1-2 hours.

• Viscosity

In the Spec Table - Viscosity is measured in Krebs Units (or Krebs-Storm Units), which are unit-less. Use them for relative comparisons among the mixtures.

By way of reference, Kreb Unit values for some common fluids are: olive oil = 20, glycerine = 30, castor oil = 90, molasses = 133.

With KU measurements from 65 to 85, Hawk Epoxies are in the range between glycerine and castor oil.

Specifications

811577014860

Product Options

| Selected | SKU # | MFG # | Availability | Size | Price | Quantity | |

|---|---|---|---|---|---|---|---|

| SKU #: 437197 | MFG #: C3-S2 | 14 In Stock Ships immediately | 0.8 Qt | $51.35 Each | |||

| SKU #: 437202 | MFG #: C3-S1 | 4 In Stock Ships immediately | 0.4 Pt | $23.72 Each | |||

| SKU #: 437207 | MFG #: C3-S3 | 3 In Stock Ships immediately | 0.87 Gal | $172.86 Each | |||

| SKU #: 450380 | MFG #: C3-S4 | Special Order Only | 10.4 Gal | $1,334.00 |