Model 117 Lever Action Pump - 30 GPM, Bronze, 1-1/2" Ports, Side Inlet

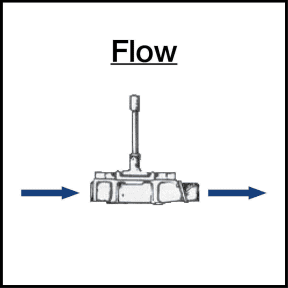

- Lever Action

- Side Inlet

Description

These high capacity, clog-free pumps are the ones to have when the batteries are toast, bilge water is sloshing over the floorboards, and you need to move a lot of water in a hurry.

If you've ever been on a sinking boat, you know what we mean - the proverbial scared man with a bucket just doesn't cut it.

Edson's heavy-duty 30 gallon per minute manual pumps are designed to be used as bilge or general purpose pumps aboard yachts or workboats.

They can pump water, sewage, fuel, or oil in a variety of applications onboard as well as on land.

These diaphragm pumps have a non-clogging, flow-thru design that can handle solids up to 1-1/4" in diameter--- socks, nuts and bolts, sand, etc. — if it flows through the hose, it goes through the pump.

They will pump 30 gpm at a typical 30 strokes per minute - that's 1 gallon per stroke - while lifting the water 5 ft and directly overboard in the process.

"Bone Dry" pumps are available in bronze (more corrosion resistant) or aluminum (lower price and lighter weight for mobile/emergency applications) in two versions - Lever-Action (shown here) or Offset Drive - each with the option of a side or bottom inlet port.

These pumps are the side inlet models.

In addition, each of these pumps is available in two port sizes (1-1/2" or 2")

They come standard with oil-resistant nitrile diaphragm and valves, but other options are available, see below.

The choice of model is based on the location and use of the pump.

We only list a few of the possibilities; please inquire at 1-800-426-6930 if you don't see the model you need.

• Comes with a 32" aluminum handle

• Choice of 1-1/2" or 2" NPT ports

• Inlet ports are male NPT, discharge ports are female NPT

• Self-priming from a dry start to 12 vertical feet

• Discharge hose head can be as high as 15 ft above the pump

• Head ring and drive arm can be rotated to any of four 90° positions

• Fabric-reinforced nitrile diaphragms and valves

• Bodies are marine grade red bronze, or anodized aluminum, all with stainless steel hardware

• Simple to maintain

A note regarding port size: Since the pumping chamber is the same size regardless of the hose diameter, one stroke always pumps the same amount of water.

However, using larger diameter ports and hoses produces less resistance, requiring approximately 20% - 30% less effort to pump. So if your application can deal with the larger hoses and thru-hulls, then choosing the larger port size will make for easier, and faster, pumping.

For large vertical lifts, use of a foot valve at the end of the intake hose will probably be required, as it will take several strokes to get the hose filled, and you don't want the water in the hose to drain out during the recovery stroke.

Heavy on the technical side...

Edson manual diaphragm pumps are incredibly versatile. In addition to marines applications, they can be used for hazmat response, drum transfer, meter pit dewatering, well monitoring, sewage disposal, grouting, spill clean-up, oil collection, tank and sump pump-out, construction site dewatering, etc.

They can be permanently mounted where they are used, or mounted to a wooden carrying board for emergency and mobile applications where the pump is carried to the application. Pre-packaged, ready-to-use, emergency kits of this type with pump, hose, hose clamps, carrying board, port fittings, and handle are available by special order.

Available in the following styles:

• Lever-Action - these horizontally mounted pumps can be located in the bilge, or suspended under the cockpit sole using a bottom inlet.

• Offset Drive - Ideal for horizontal mounting on the backside of a bulkhead, with the drive axle extending through the wall and the handle moving parallel to the wall - often used with a bottom inlet. They are also useful where vertical clearance is limited.

• Vertical Mount (18 gpm Compact Model only) - allows for mounting on a wall or bulkhead, with the handle vertical and moving in and out from the wall

• Seat Riser (18 gpm Compact model only) - mounted behind a bulkhead or behind a seat riser in the cockpit, with the handle sticking out horizontally and moving up and down

Pump outputs provided are approximate, as output in a particular installation is affected by pump style, total vertical distance pumped, length of hose, fittings used, viscosity of fluid being pumped, bends in the plumbing lines and fittings, etc. — before even taking real-world stroke rate into account.

Edson diaphragm pumps are available with Nitrile (standard), Viton®, and Hypalon Elastomer diaphragms.

Valve assemblies are available only in Nitrile (standard) and Viton.

Nitrile is a strong all purpose material good for oily water, sewage, dewatering and general waste water applications.

Hypalon is good for similar applications as nitiles, but is best in applications where the outer surface of the diaphragm is exposed to ozone from electrical devices, or exposed to sunlight regularly.

Viton is best when pumping waste or liquids containing gasoline, biodiesel, or liquids containing other hydrocarbons.

If necessary, check appropriate chemical compatibility charts to determine which to order.

A variety of strainers and foot (check) valves with strainers are available for these pumps by special order; please inquire at 800-426-6930.

Specifications

Product Options

| Selected | SKU # | MFG # | Availability | Port (Material) | Material | Price | Quantity | |

|---|---|---|---|---|---|---|---|---|

| SKU #: 192639 | MFG #: 117AL-150 | Special Order Only | 1-1/2" NPT | Aluminum | $1,080.00 | |||

| SKU #: 431065 | MFG #: 117AL-200 | Special Order Only | 2" NPT | Aluminum | $1,070.00 | |||

| SKU #: 455441 | MFG #: 117BR-150 | Special Order Only | 1-1/2" NPT | Bronze | $1,405.53 |